Cucuteni-Cetățuia (jud. Iași)

A key focus of the research was the identification and uncovering of a pottery firing kiln (dated to the Cucuteni B phase), situated near the newly identified defensive ditch. The installation is of the two-chamber type, with vertical draft, and is partially dug into the ancient soil. The particularity of this kiln lies in the technical solution chosen for fuel supply: instead of a classic frontal feeding pit, the kiln featured an elongated, tunnel-type fire mouth, placed laterally, which fed a single main channel, with the heat subsequently distributed through connecting tunnels. This discovery is essential for the project, demonstrating the existence of the necessary infrastructure for standardized and high-volume ceramic production right in the eponymous settlement. A second kiln, partially destroyed, was identified right on the edge of the exterior defensive/delimitation ditch. Unfortunately, this was heavily damaged both at the top, by contemporary agricultural work, and in the eastern half, by the construction of the ditch. Thus, the two channels in the lower chamber were partially preserved. They appear as elongated, heavily burnt enclosures. It is unusual that the two channels are neither symmetrical nor aligned: the northern channel is longer (1.20×0.55 m), with the western end being more pointed and rounded; the southern channel is quasi-rectangular, shorter (0.90×0.50 m). No connections were observed between the two channels, as in the case of the kiln investigated in the previous campaign. It seems that it was constructed and used prior to this last ditch, being decommissioned and partially destroyed by its construction; it is possible that the potter rebuilt their kiln further towards the interior of the settlement. A third kiln was only identified, near the other two, and will be investigated next year.

Dumbrăvița-Tarlaua Iezer (jud. Iași)

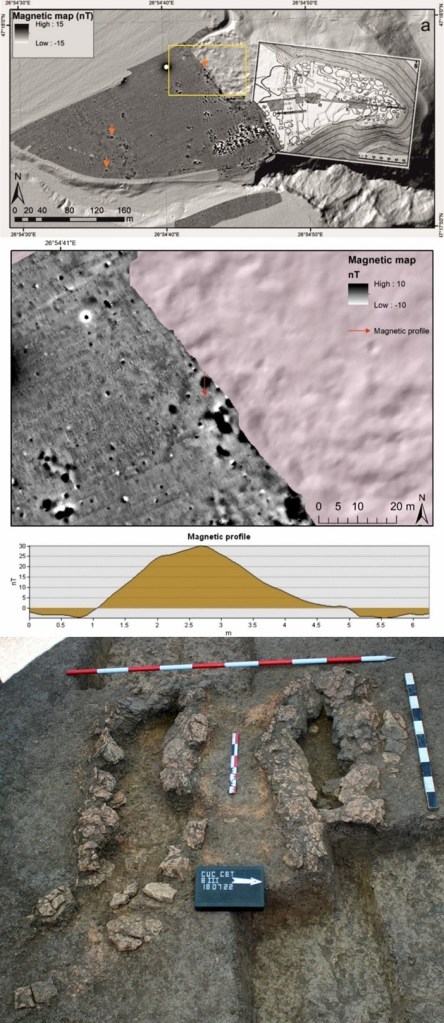

Here is the translation into English: In the campaign of the summer of 2025, the research focused on the southwestern area of the site, where the magnetometric map indicated the presence of strong dipolar anomalies. Two test trenches were opened for verification, which confirmed the existence of two ceramic firing kilns, both strategically placed, adjacent to the settlement’s defense ditch. From a constructive point of view, both installations are of the two-chamber, vertical-draft type. The lower chambers (combustion chambers) were excavated into the ancient soil, featuring a structure with two fire channels delimited by a saved median wall. The upper chamber (the vessel chamber), built on the surface, has not been preserved; however, the presence of fragments of highly fired and deformed clay slabs, identified at the bottom of the channels, suggests that the separation of the two registers was done by means of a grate formed of slabs. The state of preservation of the complexes is poor, being partially affected by intensive contemporary agricultural work. Furthermore, the integrity of the combustion chambers was compromised by a recent ditch, dug for an irrigation pipe. This intervention almost completely destroyed the southern part of the channels (the area of the fire mouth and the physical connection to the defense ditch), elements that could only be documented based on the residual thermal imprint (burnt sterile soil) preserved at the base.

* Kiln C1 (Western): Based on the preserved elements, a round or rectangular shape with rounded corners is estimated, with a diameter of approximately 2 m. The fire channels had dimensions of approx. 1.10 x 0.75 m

* Kiln C2 (Eastern): Located approximately 4 m to the east, this one likely presented a more elongated morphology (approx. 2.50 m long and 1.80 m wide), with larger channels (1.60 x 0.75 m).

Ursoaia (jud. Iași)

Archaeological excavations guided by magnetometry have brought to light a firing installation that redefines the known standards for prehistoric ceramic production in Southeast Europe. An extremely well-preserved two-chamber, vertical-draft kiln was uncovered, whose architecture and dimensions are exceptional.T he kiln was ingeniously built into the slope of the defensive ditch, taking advantage of the stability of the soil and protection from the wind. The lower chamber (combustion chamber) has impressive dimensions, approximately 3.10 x 2.40 m, resulting in an active firing surface of over 7 m2. This is significantly larger than the typical surface areas of known Cucuteni-Trypillia kilns. The structure of the combustion chamber is complex, consisting of four longitudinal fire channels that span the entire length of the chamber. These are separated by three massive clay supports and bordered by a continuous peripheral threshold that supported the floor of the upper chamber. The floor system (grate) was made of large modular slabs (approx. 60 x 35 x 8 cm), with a trapezoidal cross-section and slightly rounded corners. The combination of wide channels and massive supports was designed to ensure uniform heat distribution and increased structural resistance to high temperatures. The lower chamber functioned as a controlled corridor for hot gases, which were channeled beneath the floor slabs before ascending into the actual firing chamber. The kiln was fueled from a stoker’s pit located in the adjacent ditch, which had been deliberately filled to create an operating platform at the level of the kiln mouth. Collapsed remains suggest the existence of a robust, vaulted superstructure without wooden reinforcement. The capacity of this kiln is estimated at several hundred medium vessels per charge, a volume that far exceeds the needs of a single household and indicates production intended for exchange or community-level distribution.